I put the tube down, pump it and sulurp it (maybe this doesn’t work quite as well as Missy Elliott’s lyrics). What I mean to say is that two weeks ago, it was time for racking, the process used to remove fermented and pressed red wine from dead yeast cells (aka., the lees) that have settled to the bottom of the tank. Removing the wine from the lees means carefully transferring the wine into a clean container through siphoning. With my one borrowed tank, I also needed to return the wine back to the original tank.

So, I gathered the materials necessary to carry out this delicate process. I opted for a plastic auto-siphon and 3/8 inch plastic tubing. There is a tool called a racking wand that you can buy, but they can be fairly pricey. Originally, Mr. B intended to come to Houston to help me with this process. But, alas, he ran out of time. So, he walked me through everything I needed to know. Mainly, avoid splashing! You want to keep splashing to a minimum so that you introduce as little oxygen as possible to your wine (which is no longer protected by a layer of CO2 like it was during fermentation).

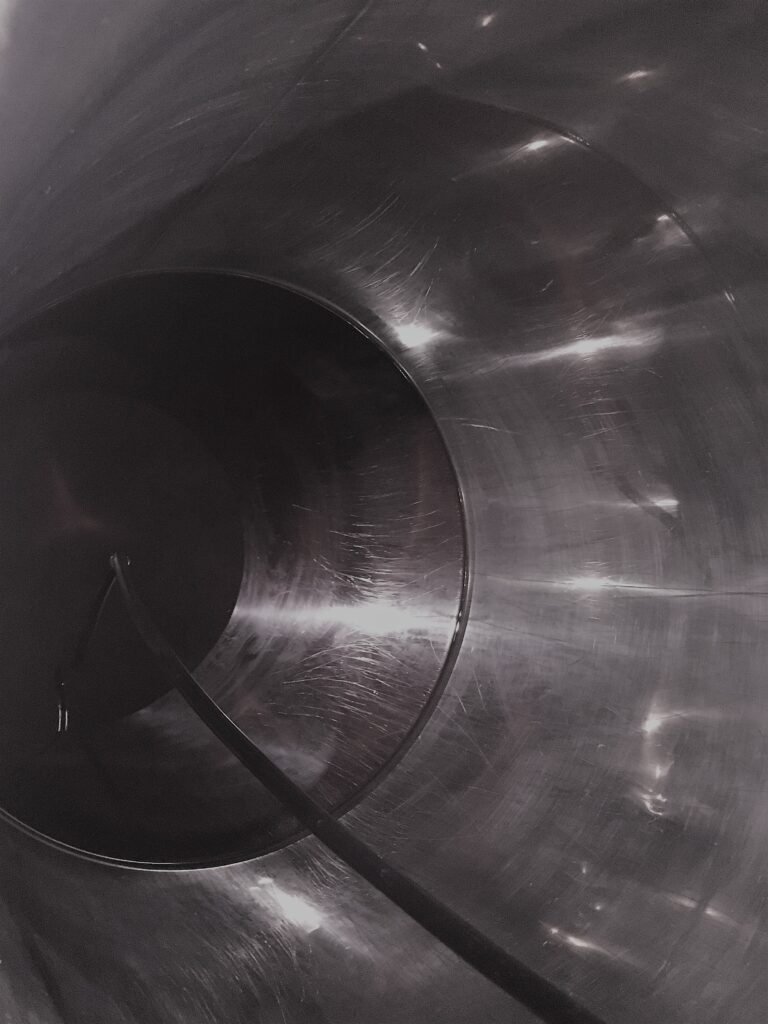

Then, I suckered my parents into helping (my husband was out of town). Racking is only doable alone if you have the right tools. But, I knew I needed help. After a few trials running sanitizing solution through the siphon and tubing, we realized that gravity was quite necessary. Luckily, I had the tank on my handy lil’ red scissor lift. So, I hoisted up the tank, took off the top, and started siphoning!

Siphoning and Beyond

Once we siphoned out most of the wine, I had to call Mr. B to see how much wine to leave behind. In essence, he said to leave an inch or so of “mud” (lees and other particles) behind. Then, we grabbed a sample to send to Mason, TX, cleaned the tank, and did the process in reverse to return the wine to the tank.

After the wine (sans the gross lees/mud) was safely returned to the tank, Mr. B advised me to “gas” the wine. Without a commercial operation, this can be a slight challenge. But, Mr. B suggested an at-home easy method using a wine preserver (combo of inert gases). So, I hooked up the wine preserver can to some tubing and pumped some gas into my wine. As mentioned above, gases are released during the fermentation process, but once the CO2 dissipates, the wine can easily be exposed to O2. Too much O2 ruins the wine. With the gassing process successful, we closed the tank and transferred it to the cellar. Phew! Racking complete!

Back into the tank

Goodnight wine!

Oops, I Forgot to Mention the Malo!

After pressing the wine, winemakers often add a cultivated malolactic bacteria to coax the wine into malolactic fermentation (MLF) before it happens naturally. You want to use a cultivated bacteria to have better control over the process and flavors. So, what is malolactic fermentation, aka. MLF, aka. ML, aka. secondary fermentation?! It is the process where bacteria converts malic acid into lactic acid, thereby softening the wine. It isn’t really a fermentation at all, but it is a conversion process.

Why do I bring this up now? Well, I added malo bacteria after pressing. But, I am still not convinced that it actually happened. Sometimes, the bacteria is slowed or stopped if SO2 is too high or if alcohol levels are too high. During racking, I grabbed a sample to be tested. I will hopefully find out soon if malolactic fermentation actually occurred! Fingers crossed.

Pingback: Road to My 1st Commercial Vintage - The Cause Urban Winery